Full Klamp Collet Chuck Catalogue

Download Catalogue

Full Swift Klamp 5-Axis Workholding Catalogue

Download Catalogue

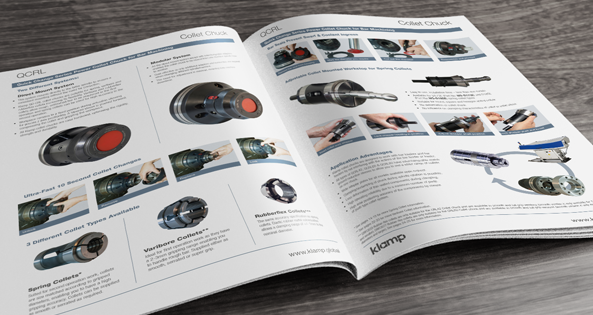

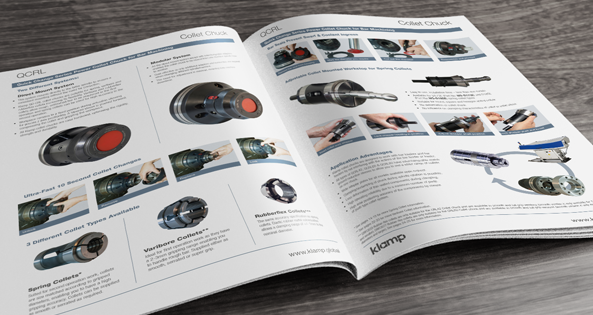

Fixed length, standard and quick change collet chuck series for bar machining. Uses cost effective industry standard spring collets for high accuracy second operations and varibore collets for first operation processes, enabling you to grip rough irregular bar stock. Available either as direct mount or with a modular mounting system.

Pull back & fixed length quick change collet chuck series for bar machining utilising a collet changing gun to change collets. Ten second collet change capability without sacrificing accuracy reduces your set up time. Collets have vulcanized rubber between the segments ensuring protection against the ingress of coolant and chips.

Pull back collet chuck series using standard high accuracy 5C and 16C Collets. The compact design gives you maximum tool clearance and the collets are available either in round, hexagon or square profiles with a smooth surface as standard and supplied in 0.5mm increments. The Low Profile series has a gripping range from 1mm to 42mm.

Rigid and accurate mandrels for workholding of internal diameters. Hydraulically (power) or manually actuated series allowing you full part access to outside diameters. Dual contact with a pull-back action against a part locator ensures highly accurate and secure rigidity of the workpiece during machining. Many customised options are available.

Standardised Dovetail; Flange Clamp and and Side Clamp work-holding options, providing a rigid & secure platform for your 5-axis machining processes; Dovetail systems allow superior tool access due to their small clamping surface. The time-proven HSK interface between the work-holder & the clamping head give optimal bending rigidity.

Supplied with a versatile mounting flange to suit multiple mounting options for 5-axis machines and NC rotary tables. Available in HSK-A40, HSK-A63 and HSK-A100 sizes, with an offline work-piece set-up procedure, it is capable for the workholder system to be exchanged within ten seconds, minimising machine downtime.

To fully automate your manufacturing process, the low-pressure hydraulic operated head is also available in HSK-A40, HSK-A63 and HSK-A100 sizes, with seating detection and air-blow. The work-holder profile that is used with the clamping head has a common interface to enable them to be handled by any general-purpose robot arm.

Full Klamp Collet Chuck Catalogue

Download Catalogue

Full Swift Klamp 5-Axis Workholding Catalogue

Download Catalogue